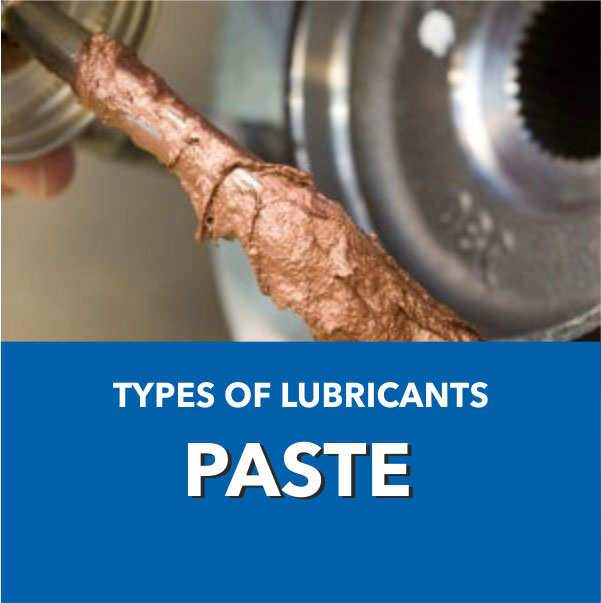

Pastes

for easy assembly and dismantling

The structure of pastes corresponds in principle to that of greases. However, the share of solid lubricants is clearly higher. Thus a reliable lubricating, parting and corrosion protection effect is ensured even when used under extreme temperature and pressure conditions and aggressive media. Pastes are used at screw threaded connections as well as for pressing in pins and bolts, at gearwheels, chucks, hinges and plain bearings.

| Characteristics |

Standard |

Description |

| Press-fit-test |

|

Provides information on the lubricating effect of pastes at a very high pressure and low sliding speed (relevant for assembly pastes) |

| Thread friction coefficient |

DIN 946 |

The coefficient of sliding friction μ when tightening screws and nuts is determined on a screw test bench (relevant for screw pastes) |

| Breakaway torque |

DIN 267-27

|

Ratio of the breakaway torque required when loosening the screwed connection to the tightening torque |

| Operating temperature |

|

Lubrication: Oil and solid lubricants are effective

Separation: After volatising of the oil separation effect through solid lubricants

|

The range of applications of pastes depends considerably on the solid lubricants contained.

|

Solid lubricant

|

Maximum operating

temperature [°C] |

Field of application |

| PTFE |

< 300 |

Assembly, media influence |

|

MoS2

|

< 450 |

Assembly, press-on processes |

| Aluminium |

< 1100 |

High-temperature screwed connections |

| Copper |

< 1100 |

High-temperature screwed connections, "anti-seize" paste, electrical conductivity |

| Nickel |

< 1400 |

Extreme-temperature screwed connections |

"Oxides"

ceramics |

< 1400 |

Extreme-temperature screwed connections, special-steel screwed

connections |